Water Chemistry: Hardness, Treatment, and Boiler Problems – Engineering Chemsitry Complete Notes by Mohan Dangi( Gold medalist)

Water Chemistry encompasses the study of water quality, hardness, treatment methods, and industrial water problems. Understanding water hardness types, softening processes, and boiler water treatment is crucial for chemical engineering, environmental science, and competitive exams like GATE and IIT-JEE.

1. Water Hardness: Types and Characteristics

Water Hardness is defined as the measure of dissolved calcium (Ca²⁺) and magnesium (Mg²⁺) ions in water. Hard water reduces soap lathering efficiency and causes scaling in boilers, pipes, and appliances.

1.1 Temporary Hardness (Carbonate Hardness)

- Caused by: Dissolved bicarbonates of calcium and magnesium [Ca(HCO₃)₂, Mg(HCO₃)₂][68][74]

- Characteristics: Can be removed by boiling the water

- Removal mechanism: Heat decomposes bicarbonates to insoluble carbonates

Chemical Reactions during boiling:

Ca(HCO₃)₂ → CaCO₃↓ + H₂O + CO₂ Mg(HCO₃)₂ → MgCO₃↓ + H₂O + CO₂

1.2 Permanent Hardness (Non-Carbonate Hardness)

- Caused by: Dissolved sulfates and chlorides of calcium and magnesium [CaSO₄, MgSO₄, CaCl₂, MgCl₂]

- Characteristics: Cannot be removed by boiling[74][77]

- Removal: Requires chemical treatment or ion exchange methods

1.3 Total Hardness

Total Hardness = Temporary Hardness + Permanent Hardness

Usually expressed in ppm (parts per million) of CaCO₃ equivalent or degrees of hardness.

2. Water Softening Methods

2.1 Lime-Soda Process

Uses calcium hydroxide (lime) and sodium carbonate (soda ash) to precipitate hardness-causing ions.

Principle: Chemical precipitation of Ca²⁺ and Mg²⁺ ions as insoluble carbonates and hydroxides.

Chemical Reactions:

- For Temporary Hardness:

Ca(HCO₃)₂ + Ca(OH)₂ → 2CaCO₃↓ + 2H₂O Mg(HCO₃)₂ + 2Ca(OH)₂ → 2CaCO₃↓ + Mg(OH)₂↓ + 2H₂O - For Permanent Hardness:

CaSO₄ + Na₂CO₃ → CaCO₃↓ + Na₂SO₄ MgSO₄ + Na₂CO₃ → MgCO₃↓ + Na₂SO₄ MgCO₃ + Ca(OH)₂ → CaCO₃↓ + Mg(OH)₂↓

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Economical for large-scale treatment | Produces large amounts of sludge |

| Reduces total dissolved solids | Requires skilled operation |

| Readily available chemicals | Not suitable for low hardness water |

2.2 Zeolite (Permutit) Process

Uses natural or synthetic sodium aluminum silicate (Na₂Al₂Si₂O₈·xH₂O) for ion exchange.

Principle: Exchange of Na⁺ ions in zeolite with Ca²⁺ and Mg²⁺ ions in hard water.

Chemical Formula of Zeolite: Na₂Al₂Si₂O₈·xH₂O (also written as Na₂Ze for simplicity)

Softening Reactions:

Na₂Ze + Ca²⁺ → CaZe + 2Na⁺ Na₂Ze + Mg²⁺ → MgZe + 2Na⁺

Regeneration: When zeolite becomes saturated, it's regenerated using NaCl brine[78][93]:

CaZe + 2NaCl → Na₂Ze + CaCl₂ MgZe + 2NaCl → Na₂Ze + MgCl₂

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Nearly complete hardness removal | Cannot treat turbid or colored water |

| Automatic and compact operation | Pre-treatment required |

| No sludge formation | Regular regeneration needed |

| Soft water contains no suspended matter | Cannot remove dissolved gases |

2.3 Ion Exchange Process (Demineralization)

Complete removal of all ions using synthetic organic resins to produce demineralized water.

Principle: Two-stage process using cation and anion exchange resins.

Process Steps:

- Cation Exchange: Water passes through strong acid cation resin (R-H)

2R-H + Ca²⁺ → R₂-Ca + 2H⁺ 2R-H + Mg²⁺ → R₂-Mg + 2H⁺ R-H + Na⁺ → R-Na + H⁺ - Anion Exchange: Effluent passes through strong base anion resin (R'-OH)

R'-OH + Cl⁻ → R'-Cl + OH⁻ R'-OH + SO₄²⁻ → R'-SO₄ + OH⁻ - Neutralization: H⁺ + OH⁻ → H₂O

Regeneration:

- Cation resin: Regenerated with HCl or H₂SO₄

- Anion resin: Regenerated with NaOH solution

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Produces high-purity demineralized water | High initial and operational costs |

| Suitable for high-pressure boiler feed | Requires skilled operation and maintenance |

| Removes both cations and anions | Sensitive to suspended solids and organics |

| Can achieve very low conductivity | Frequent regeneration required |

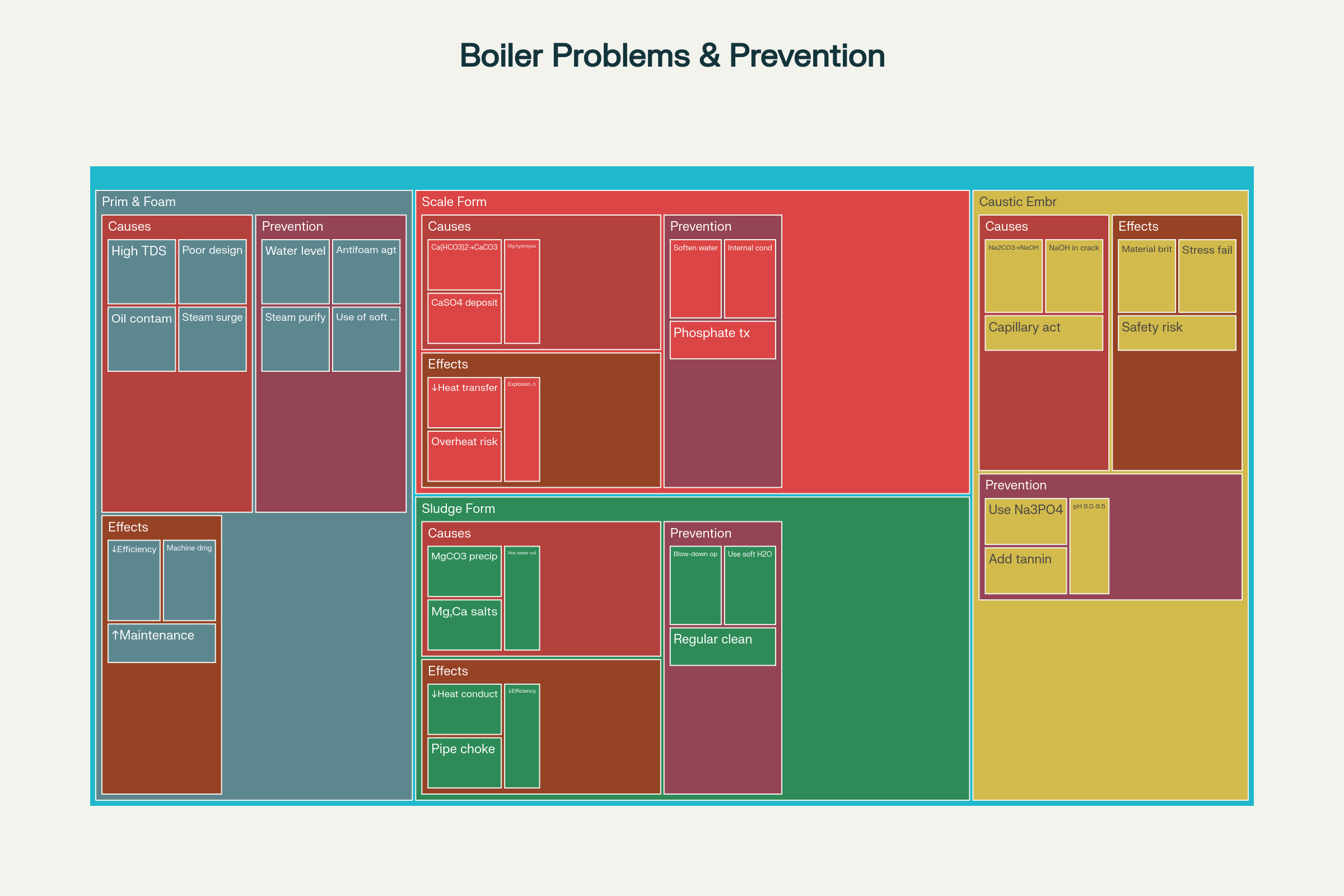

3. Boiler Water Problems

When hard water is used in boilers, several problems arise that affect efficiency and safety.

3.1 Scale Formation

Definition: Hard deposits that firmly stick to the inner walls of boilers.

Causes:

- Decomposition of calcium bicarbonate:

Ca(HCO₃)₂ → CaCO₃↓ + H₂O + CO₂

(Forms soft scale in low-pressure boilers) - Deposition of calcium sulfate: Solubility decreases with temperature, completely insoluble in superheated water

- Hydrolysis of magnesium salts:

MgCl₂ + 2H₂O → Mg(OH)₂↓ + 2HCl

Disadvantages:

- Reduces heat transfer efficiency

- Causes overheating and possible boiler explosion

- Increases fuel consumption

- Difficult to remove (requires hammer and chisel)

Prevention:

- Use of softened water

- Internal conditioning with phosphates

- Regular blow-down operations

3.2 Sludge Formation

Definition: Soft, loose, slimy precipitates formed within the boiler.

Causes: Formed by substances with greater solubility in hot water than cold water:

- MgCO₃, MgCl₂, CaCl₂, MgSO₄

- Precipitate at comparatively cooler portions of boiler

Disadvantages:

- Poor heat conductor, wastes fuel

- Decreases boiler efficiency

- Causes choking of pipes and fittings

- Settles in regions of poor water circulation

Prevention:

- Use softened water

- Frequent blow-down operation (partial removal of concentrated water)

- Make-up water addition after blow-down

3.3 Priming and Foaming

Priming: Formation of wet steam due to water droplets being carried with steam.

Foaming: Formation of stable bubbles above water surface that are carried by steam.

Causes:

- High concentration of dissolved solids (alkali salts, chlorides)

- Improper boiler design

- Very high water level

- Sudden increase in steam production rate

- Presence of oil and organic matter (foaming)

Effects:

- Reduces boiler efficiency

- Decreases life of machinery parts

- Increases maintenance costs

- Can cause failure of superheaters

Prevention:

- Maintain proper water level

- Use softened water

- Install mechanical steam purifiers

- Add antifoaming agents (synthetic polyamides)

- Improve boiler design

3.4 Caustic Embrittlement

Definition: Phenomenon where boiler material becomes brittle due to accumulation of caustic substances.

Mechanism:

- Na₂CO₃ in boiler water decomposes:

Na₂CO₃ + H₂O → 2NaOH + CO₂

- NaOH flows into minute cracks by capillary action

- Water evaporates, concentrating NaOH

- NaOH attacks iron, forming sodium ferrite:

Fe + 2NaOH → Na₂FeO₂ + H₂

Effects:

- Embrittlement of boiler parts, especially stressed components (bends, joints, rivets)

- Can cause catastrophic boiler failure

- Safety hazards for personnel

Prevention:

- Use sodium phosphate instead of sodium carbonate as softening agent

- Add tannin or lignin to block hair-line cracks

- Add sodium sulfate to seal cracks

- Maintain boiler water pH between 8.0-8.5

3.5 Boiler Corrosion

Definition: Chemical and electrochemical attack on boiler materials.

Causes and Mechanisms:

3.5.1 Dissolved Oxygen Corrosion

2Fe + 2H₂O + O₂ → 2Fe(OH)₂ (rust formation) Fe(OH)₂ + O₂ → Fe₂O₃·2H₂O

Prevention:

- Add oxygen scavengers: N₂H₄ + O₂ → N₂ + 2H₂O

- Use sodium sulfite: 2Na₂SO₃ + O₂ → 2Na₂SO₄

- Mechanical deaeration

3.5.2 Dissolved CO₂ Corrosion

Ca(HCO₃)₂ → CaCO₃ + H₂O + CO₂ CO₂ + H₂O → H₂CO₃ (makes water acidic)

Prevention:

- Treatment with ammonium hydroxide: 2NH₄OH + CO₂ → (NH₄)₂CO₃ + H₂O

- Mechanical deaeration

3.5.3 Dissolved Salt Corrosion

MgCl₂ + 2H₂O → Mg(OH)₂ + 2HCl Fe + 2HCl → FeCl₂ + H₂ FeCl₂ + 2H₂O → Fe(OH)₂ + 2HCl

Prevention: Internal and external water conditioning

4. Internal Water Treatment Methods

4.1 Carbonate Conditioning

Addition of sodium carbonate to convert scale-forming sulfates into easily removable sludge:

CaSO₄ + Na₂CO₃ → CaCO₃↓ + Na₂SO₄ (sludge)

4.2 Phosphate Conditioning

Addition of sodium phosphates to form non-adherent phosphate sludges:

3CaCl₂ + 2Na₃PO₄ → Ca₃(PO₄)₂↓ + 6NaCl 3MgSO₄ + 2Na₃PO₄ → Mg₃(PO₄)₂↓ + 3Na₂SO₄

Types of Phosphates Used:

- Na₃PO₄ (alkaline) - when alkalinity is low

- Na₂HPO₄ (weakly alkaline) - when alkalinity is sufficient

- NaH₂PO₄ (acidic) - when alkalinity is high

5. Solved Numerical Examples

Example 1: Hardness Calculation

Problem: A water sample contains 120 mg/L of Ca²⁺ and 80 mg/L of Mg²⁺. Calculate the total hardness in mg/L as CaCO₃.

Solution:

- Hardness due to Ca²⁺ = (120 × 100) / 40 = 300 mg/L as CaCO₃

- Hardness due to Mg²⁺ = (80 × 100) / 24 = 333.33 mg/L as CaCO₃

- Total hardness = 300 + 333.33 = 633.33 mg/L as CaCO₃

Example 2: Lime-Soda Process Calculation

Problem: Calculate lime and soda ash required to soften 10,000 L of water containing:

- Ca(HCO₃)₂: 162 mg/L

- Mg(HCO₃)₂: 146 mg/L

- CaSO₄: 136 mg/L

Solution:

- For Ca(HCO₃)₂: 1 mole requires 1 mole Ca(OH)₂

162 mg/L ÷ 162 = 1 mmol/L × 74 = 74 mg/L Ca(OH)₂ - For Mg(HCO₃)₂: 1 mole requires 2 moles Ca(OH)₂

146 mg/L ÷ 146 = 1 mmol/L × 2 × 74 = 148 mg/L Ca(OH)₂ - For CaSO₄: 1 mole requires 1 mole Na₂CO₃

136 mg/L ÷ 136 = 1 mmol/L × 106 = 106 mg/L Na₂CO₃ - Total Ca(OH)₂ required = 74 + 148 = 222 mg/L × 10 L = 2.22 g

- Total Na₂CO₃ required = 106 mg/L × 10 L = 1.06 g

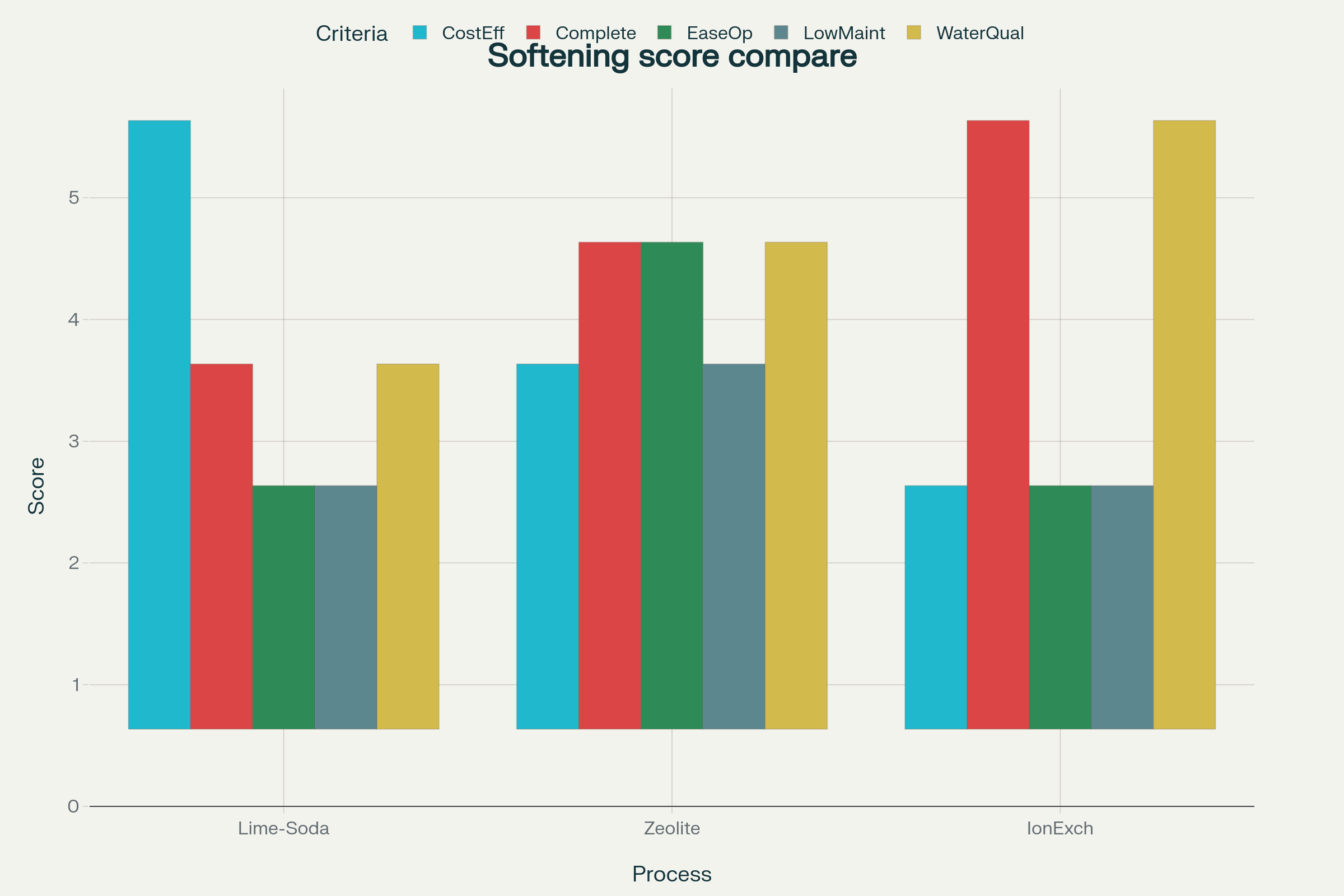

6. Comparative Analysis of Water Treatment Methods

| Parameter | Lime-Soda | Zeolite | Ion Exchange |

|---|---|---|---|

| Principle | Chemical precipitation | Ion exchange (Na⁺ ↔ Ca²⁺, Mg²⁺) | Complete demineralization |

| Hardness Removal | 80-90% | 95-98% | 99-100% |

| TDS Reduction | Yes | No (increases due to Na⁺) | Yes (complete removal) |

| pH Effect | Increases pH | No change | No change |

| Sludge Production | High | None | None |

| Operating Cost | Low | Medium | High |

| Suitable for | Municipal treatment | Industrial process water | High-pressure boilers |

7. Water Quality Standards and Testing

7.1 Hardness Classification

| Hardness Level | mg/L as CaCO₃ | Description |

|---|---|---|

| Soft | 0-60 | No treatment needed |

| Moderately Hard | 61-120 | Some treatment beneficial |

| Hard | 121-180 | Treatment recommended |

| Very Hard | >180 | Treatment essential |

7.2 Boiler Water Quality Limits

| Parameter | Low Pressure | Medium Pressure | High Pressure |

|---|---|---|---|

| Total Hardness (mg/L) | <5 | <2 | <0.5 |

| Total Dissolved Solids (mg/L) | <3000 | <1000 | <500 |

| pH | 10.5-11.5 | 9.0-10.0 | 8.5-9.5 |

| Silica (mg/L) | <150 | <50 | <20 |

8. Environmental and Economic Considerations

8.1 Environmental Impact

- Lime-soda process: Generates large amounts of CaCO₃ sludge requiring disposal

- Zeolite process: Brine discharge during regeneration increases salinity

- Ion exchange: Acid and alkali waste during regeneration

8.2 Energy Considerations

- Scale formation increases energy consumption by 10-15% for every mm of scale thickness

- Proper water treatment can reduce fuel costs by 20-30%

- Preventive treatment is more economical than reactive maintenance

9. Modern Developments and Advanced Treatments

9.1 Membrane Technologies

- Reverse Osmosis (RO): Physical separation using semi-permeable membranes

- Nanofiltration: Selective removal of divalent ions

- Electrodialysis: Ion separation using electric potential

9.2 Alternative Softening Agents

- EDTA and other chelating agents: Form stable complexes with hardness ions

- Polyphosphates: Sequester hardness ions without precipitation

- Magnetic treatment: Claims to alter crystal structure (controversial)

10. Competitive Exam Focus Points

10.1 Key Concepts for GATE/IIT-JEE

- Differentiate between temporary and permanent hardness with examples

- Calculate lime and soda ash requirements for given water composition

- Understand zeolite regeneration chemistry and capacity calculations

- Analyze boiler problems and suggest appropriate prevention methods

- Compare water treatment methods based on efficiency and economics

- Interpret water analysis reports and recommend treatment strategies

10.2 Important Chemical Reactions

- Temporary hardness removal: Ca(HCO₃)₂ + Ca(OH)₂ → 2CaCO₃ + 2H₂O

- Permanent hardness removal: CaSO₄ + Na₂CO₃ → CaCO₃ + Na₂SO₄

- Zeolite exchange: Na₂Ze + Ca²⁺ → CaZe + 2Na⁺

- Ion exchange: 2R-H + Ca²⁺ → R₂-Ca + 2H⁺

- Caustic embrittlement: Na₂CO₃ + H₂O → 2NaOH + CO₂

11. Revision Summary

11.1 Essential Definitions

- Water Hardness: Concentration of Ca²⁺ and Mg²⁺ ions causing reduced soap lathering

- Temporary Hardness: Due to bicarbonates, removed by boiling

- Permanent Hardness: Due to sulfates/chlorides, requires chemical treatment

- Scale: Hard deposits on boiler walls reducing heat transfer

- Sludge: Soft precipitates causing poor heat conduction

11.2 Key Formulas

- Hardness as CaCO₃: (Ion concentration × 100) / Atomic weight of ion

- Zeolite capacity: Usually expressed as kg CaCO₃ per m³ of zeolite

- Lime requirement: Based on stoichiometry of hardness-causing salts

11.3 Treatment Selection Criteria

- Municipal supply: Lime-soda process for large-scale, cost-effective treatment

- Industrial process: Zeolite for moderate hardness, consistent quality

- High-pressure boilers: Ion exchange for complete demineralization

- Small installations: Packaged zeolite or RO systems

This comprehensive Water Chemistry guide covers all essential aspects of water hardness, treatment methods, and boiler problems. The combination of theoretical understanding, practical applications, solved examples, and comparative analysis provides a complete foundation for academic success and professional practice in water treatment engineering.